What’s in the DSpOC Lab?

Cutting Edge Technology and Research

One of the pillars of DSpOC is to build on and support existing space research in Delaware. Part of that goal is to provide a shared lab with research infrastructure available to multiple groups at the University of Delaware. Students and research scientists alike make use of The Lab for a multitude of purposes. So, what is in The Lab?

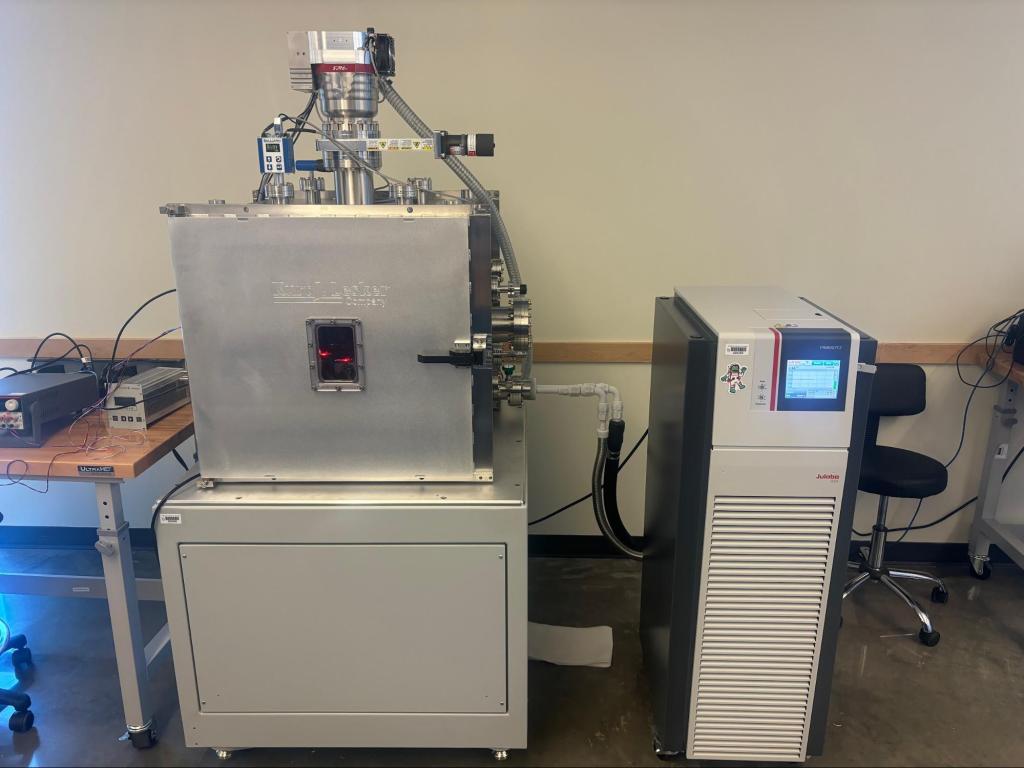

An invaluable, and expensive, resource in the DSpOC Lab is the Thermal Vacuum chamber, T-Vac for short. This is a 3x3x3 foot cube of steel and aluminum meant to test equipment that will go into environments with very low pressures (like space!) (Figure 1). Manufactured by Kurt J. Lesker Co., this box is a feat of human engineering, and is able to hold up under an atmosphere of pressure difference. Additionally, the chamber includes various ports to allow electrical connections from the outside to the inside so researchers can get data from their electronics as they are experiencing the space-like environment. Another important port is the nitrogen purge port. This allows the chamber to be dehumidified, replacing all room air, which potentially has water vapor in it, with pure nitrogen. This is required because, as you will soon find out, the chamber also gets cold, and cold water becomes ice, and ice can harm electronics.

At the base of the T-Vac chamber is a “cold plate”. The cold plate has a serpentine path that a coolant passes through for an efficient transfer of heat. Anything in contact with the plate will eventually reach an equilibrium temperature, either cold or hot. The Julabo Presto A80 works as both a chiller and a heater as it is rated to output between -80℃ to 250℃ (Figure 2). The liquid that runs through the A80 is the Julabo Thermal P90, a silicone based thermal fluid. This chiller connects to the T-Vac chamber through two pipes, one input and one output. The chiller cools the liquid down to a user input temperature, and pumps it through the input pipe to the cold plate. After passing through the entire plate, the liquid returns to the chiller. This cycle continues until and after the plate has come into equilibrium with the coolant temperature. Notably, when we go down below 0℃, as we often do, the pipes between the chiller and the T-Vac chamber will accumulate frost from condensation, reminiscent of the triple dog dare scene from A Christmas Story (Figure 3).

Figure 2. Julabo Presto A80 Chiller and Heater Unit

Figure 3. Coolant pipes accumulating frost at -50℃. I triple dog dare you

Things do not magically show up to be tested in the T-Vac chamber. No, there is typically hours, days, and months of work and preparation before electronics are ready for T-Vac testing. An electrostatic discharge (ESD) workstation is perfect for assembly and prototyping of electronics. Operators wear a wrist strap that electrically connects them to an ESD monitor, which ensures that the user is directly connected to ground. If the operators are not “strapped in,” excess charge can accumulate and result in damaging electronics, or even shocking the operator. Also, ESD safely guards against electrocution if the operator were to come in contact with a large power source. In the DSpOC Lab, the ESD workstation consists of a 6 foot table with an ESD mat placed over it (Figure 4). A soldering station and many breadboards adorn the surface for electrical assembly and testing.

Also for assembly in the lab is an Air Science Pureair Laminar Flow Hood (Figure 5). The laminar flow hood protects mechanical components during assembly from contaminants. The hood pushes clean air from the top out the front so that dust and other particles are constantly removed from the assembly area. During assembly of space rated equipment, a sterile environment is critical to limit unpredicted failures.

This equipment is designed to be used by all facets of space research at the University of Delaware. The shared space benefits from having state-of-the-art equipment that maybe one singular research group could not justify spending money on, but multiple groups have interest and need for their research. The thermal vacuum chamber is an especially unique and important resource for Delaware as a whole as there is no other thermal vacuum chamber in the entire state. Previously, scientists and researchers would have to pack up and take their experiments to a distant facility with a thermal vacuum chamber. But now they can stay on campus and walk at most 15 minutes to the DSpOC Laboratory for a space simulation test.

Leave a comment